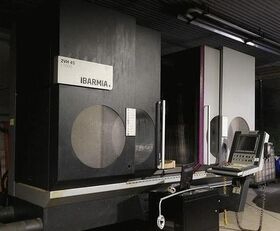

Inventhor Iridium 200 machining centre

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Marke: Inventhor

General Features

Machine Type

4-axis vertical lathe

Manufacturer

Inventhor

Model

Iridium 200

Operation

Designed for series production with dual movable main spindles allowing workpiece change during production time

Applications

Ideal for pre-formed chuck workpieces

suited for short machining times and medium to large batch sizes

Two-Sided Machining

Supports machining with different cycle times for operations OP10 and OP20

Only 492,000 machine cycles

Automation

Options

Equipped with either a conventional automation solution or can be integrated with an industrial robot for enhanced flexibility

Technical Data (Overview)

Circulation Diameter

200 mm (automated)

Travel Distances

X-axis – 220 mm

Z-axis – 280 mm

Loading Time

Approximately 3.0 seconds

conducted in parallel with production time

Workpiece Change

Around 2.0 seconds for changing the workpiece into the working area

Main Spindles

2 main spindles with A6 spindle flanges

Tool Configuration

Includes 2 disc turrets

each 8-fold

with VDI 30 or an optional VDI 40 configuration

Find more here

show contacts

Contact us at - show contacts