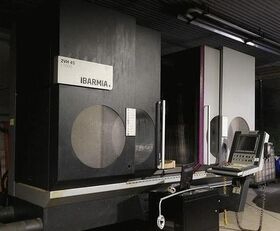

Licon LiFLEX II i³ 766 machining centre

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Marke: Licon

Licon LiFLEX II i³ 766 DT B22

Precise mechanical machine

Operating hours

approx. 40,148 h

power

The LiFLEX II i³ 766 sets new standards with its groundbreaking i³ technology

which combines two spindles in one machine

With double spindles and maximum accuracy

it enables a stable and precise machining process like never before

Thanks to independently adjustable motor spindles in the Z axes and a 5-axis configuration

this machine offers maximum performance in every operation. The generous spindle distance of 750mm and the generous working area of X 750 Y 660 Z 650 enable the machining of a wide range of workpieces with ease

Temperature sensors with innovative algorithms reduce the influence of different temperatures on the positioning accuracy of the motor spindles

while the Watt Pilot ensures reliable drill breakage control

The LiFLEX II i³ 766 is not only powerful

but also extremely flexible. With an HSK 63 tool holder with planar system control and a tool magazine with 98 (2x49) spaces

it offers the necessary versatility for demanding manufacturing tasks

Additionally equipped with an RFID tool chip

a Knoll coolant system with KSS and the option of converting to MQL

this system is perfect for precise production in the shortest possible time and a stable process

i³-Technologies

Two one spindlers in one machine

Double spindles and maximum accuracy

Independently adjustable motor spindles in the Z axes

Independent in X

Y and Z

Spindle distance 750mm

Working stroke X 750 Y 660 Z 650

Temperature sensors with associated algorithms reduce the influence of different temperatures on the positional accuracy of the motor spindles in the machining process

Maximum performance thanks to 5-axis configuration

The LiFLEX II i³ 766 is a machine that can be loaded directly

with a double swivel carrier in a 5-axis combination

HSK 63 tool holder with planar system control

Tool magazine with 98 (2x49) spaces

Watt Pilot as drill breakage control

RFID tool chip

Knoll coolant system with (KSS)

Converting to MMS is possible at any time (MMS – installed)

Workpiece system control using dynamic pressure testing

Find more here

show contacts

Contact us at

show contacts