Maka PA 37 machining centre

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

MAKA Systems GmbH

Type: PA 37

Machining length: 11 m

Operating hours: 23.792

Spindle exchange: 08/2018

MAKA CNC 5-axis machining center PA 37

for machining of aluminum profiles

and (with clamping surface to be realized clamping surface) for aluminum sheets / plates

machining

Version

with NC support crosshead positioning

and with widened machine

base frame to accommodate the required

required drag chains

and with hydraulic workpiece clamping

Machine in travelling gantry design with

drive on both sides (gantry drive)

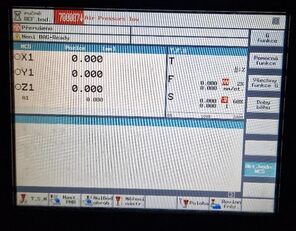

CNC-control BWO 930 in mobile operating

for 5-axis milling with RTCP function

memory 1 mB

with integrated PC with low power processor

1 GHz

hard disk 120 gB

with Windows-XP

10" touch-screen display with touch-screen

computer keyboard

Connections

1 x VCS for screen

4 x USB

1 x mouse

1 x keyboard

1 x RS 232

Ethernet 100 mB for connection to the CPU

network connection: Ethernet 10 mB

TCP/IP

at the CPU in the control cabinet

Travel ranges (axis designations X/Y exchanged for

exchanged over standard) =

X-axis approx. 12.100 mm

Y-axis approx. 2.350 mm

Z-axis approx. 800 mm

A-axis 196 ° (swivel axis +/- 98°)

B-axis 540 ' (rotary axis)

Rapid traverse speed Y-/X-axis 45 m/min

Z-axis 24 m/min

A-/C-axis 10,000 °/min

Machining unit

1 universal unit for 5-axis milling with

integrated swivel and rotary axis

Milling spindle water-cooled

nominal power 20 kW from 12.000 1/min

speed

infinitely variable up to 24.000 1/min. (236411)

with axis control left/right rotation for gear

thread cutting up to M 12

Room extraction for machining in 5-axis operation

operation

Tool interface HSK-F63 for automatic tool change

tool change

1 chain tool magazine with 32 places for tools up to

tools up to 90 mm 0 each

or up to max

max. 160 mm 0 and 160 mm total length from spindle (= with

length from spindle (= with 70 mm basic length for tool

for tool holder + 90 mm projection length)

Special tools up to 280 mm total length can be

be deposited and automatically exchanged

A saw blade with up to 350 mm 0 can be deposited in the

magazine and changed automatically (occupies

(occupies 5 storage places)

The magazine is arranged in the unit output position

sition. Partition wall between magazine and working

area for protection of tools against direct

direct flying chips

Milling spindle and 2 magazine positions set up

for angle/probe heads with torque support

torque support

Find more here

show contacts

Contact us at

show contacts